Background

In recent years, the booming rise of the new energy vehicle industry has attracted people’s eyes, behind which is a high dependence on information products. This trend is particularly significant in the field of PCB manufacturing which is the core of electronic components. Compared with the traditional fuel vehicles, the new energy vehicle has higher requirements for quality control to adapt to the market.

Therefore, how to improve the making efficiency of high-quality PCB has become the key for the entire industry. In this vigorous speed-and-quality competition, Automated Optical Inspection (AOI) technology is in the spotlight in the field of circuit board inspection due to its superior inspection efficiency.

However, AOI technology still faces the dual challenges of energy consumption and increased time cost when dealing with the manual re-inspection of defective products generated by dozens of machines in large manufacturers.

To deal with this issue, Kinan Technology provides its innovative IP KVM Matrix system that is a superior solution. This system can achieve the optimization of the manual review process through effective integration and centralized management. It can not only improve inspection efficiency but also reduce operating costs.

Application of Industry

Then, how to use the KVM over IP matrix system in the field of AOI? In AOI, once the abnormality of a product is found, a manual re-inspection prompt will be triggered. However, this decentralized re-inspection method consumes too much time and personnel sources, which isn’t good for improving productivity and saving costs.

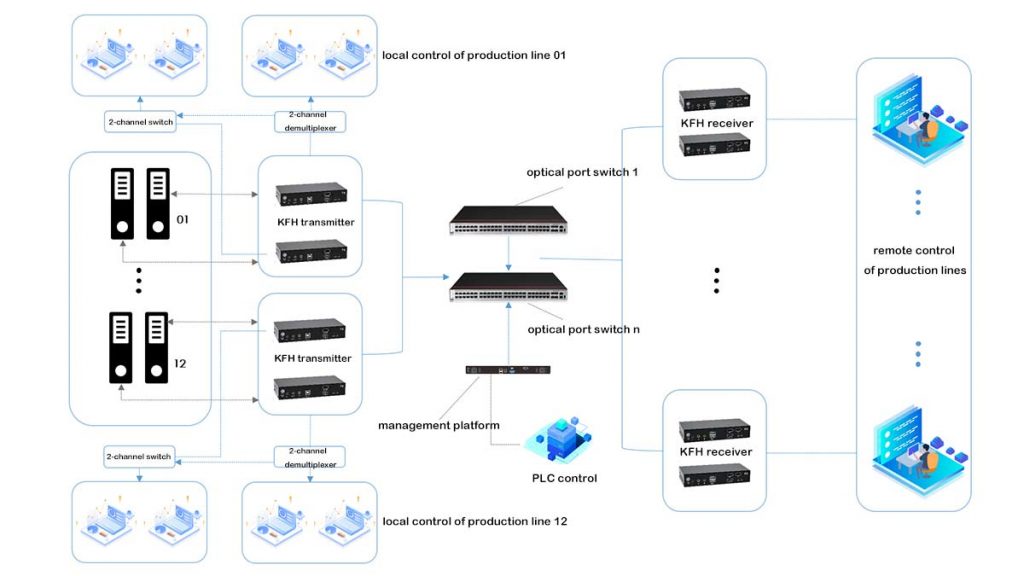

The IP KVM matrix system connects all AOI devices through matrix networking technology to build a highly integrated, flexible, and controllable central management platform.

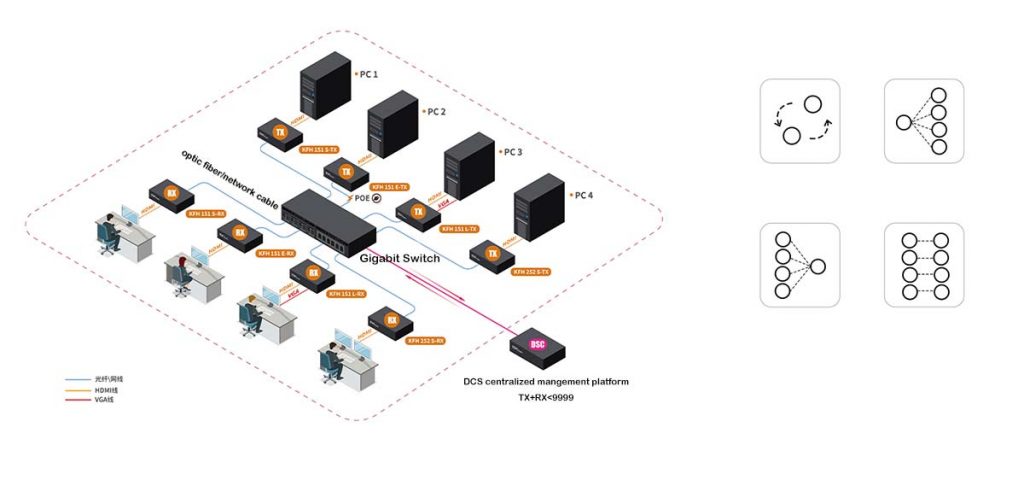

With the support of the Kinan IP KVM matrix system, the staff can easily realize remote monitoring and scheduling of any AOI device in the network by setting up KVM send port (KFH series TX device), receive port (KFH series RX device), with efficient network switch, user host, HD monitor, and a set of mouse and keyboard. Whether you switch the inspection screen or control it in real-time, there is no need to worry about delay or switching, ensuring the continuity and accuracy of the re-inspection work.

Client Issue

As a pioneer in the KVM field, Kinan Technology customizes an IP KVM Matrix system for the AOI workshop of a famous industry giant. Its AOI workspace is an essential part of the production process. Especially, the management of the time and space of the manual re-inspection needs to be optimized.

Solution

KVM over IP matrix system can realize the remote centralized control of multiple devices, making the operation easier without space limitations. In practical application, Kinan KVM over IP matrix system has played an important role in command and dispatch capabilities and has completed the instantaneous arbitrary switching between multiple AOI devices in the application process.

The features of Kinan IP KVM matrix system in this project

Achieve remote centralized control.

IP KVM matrix system has flexible scalability, supporting long-distance one-to-one, one-to-many, many-to-one, and many-to-many deployments. The staff can control and monitor all images of the target servers easily, which extremely improves flexibility and efficiency.

Achieve human-machine separation.

The staff can just stay before the control platform to monitor multiple AOI devices instead of running among all devices frequently to check them. Thanks to this feature, the staff can work easily and Improve recheck accuracy.

Support real-time control.

Kinan Technology applies IP network transmission technology with high bandwidth and low latency, which can ensure the real-time and clarity of the images. What’s more, the in-built security system can guarantee the safety of the transmitted data, preventing from illegal access and mistaken operation.

Support flexible dispatch.

Realize efficient management in different scenarios and improve the flexibility and response speed of the whole production line.