- Home

- Factory

Factory

Taking Pride in In-House Manufacturing

Welcome to Kinan’s comprehensive manufacturing facility, where every KVM product in our inventory is produced from the ground up.

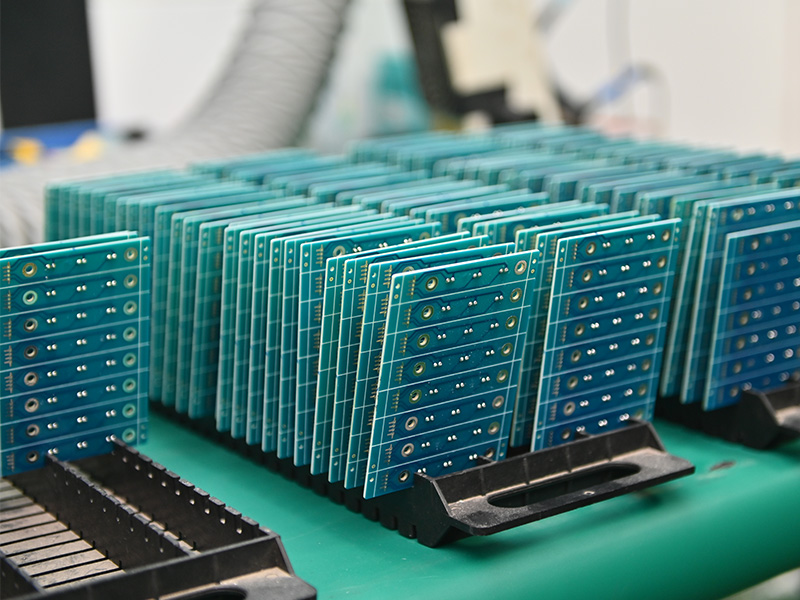

Our world-class facility has a production workshop with multiple production lines, each equipped with professional machines to tackle the assembly of semi-finished and finished products. There’s also a cutting-edge quality workshop with three inspection lines that handles the inbound, outbound, and packaging audits to ensure they pass industry standards. We also have an aging room and a dedicated testing department for intensive testing and quality control.

In addition to our production and quality workshops, we also have five warehouses with different assignments and temperature regulations to efficiently manage the completed products and raw materials.

Explore Our Factory

Take a tour of our world-class production facility with each workshop packed with professional equipment.

Only the Best Raw Materials

Knowing that our KVM products are only as good as the materials used in making them, we invest in sourcing the best raw materials for our products.

Each key component, from sheet metals to small electronic parts, is procured from top industry brands across the globe, ensuring they meet quality standards while consistently performing even in harsh environments. And since we’ve been working with them for more than a decade, we’re sure of the pieces we’re getting every time.

In addition to the top-notch raw material procurement process, we also inspect the pieces upon receipt for RoHS compliance.

Quality is Kinan’s Top Priority

At Kinan, quality is at the top of our production philosophy. Our team of expert inspectors runs meticulous audits and uses professional testing equipment to test all the finished products to guarantee optimal and consistent performance despite long years of use.

Raw Material Inspection

Our team takes time to check all incoming raw materials as we receive them from the manufacturer. They go through several testing processes, ensuring they fit our KVM solutions and work perfectly upon assembly.

- Tension and swing test for wires

- Salt spray test, hundred grid test, and alcohol test for sheet metals and hardware pieces. Alcohol test for keyboards

- High and low temperature tests for screens

- Aging and high and low temperature tests for power supplies and boards

Finished Product Testing

After assembly, our KVM products go through a series of intensive tests to check their performance, consistency, and durability based on industry benchmarks.

- Appearance inspection: Appearance standards, screws, silk screen

- Structural inspection: specifications, dimensions, mechanical functions

- Performance test: keyboard, mouse, display screen, switching function, button function,

- Label identification inspection: model specifications

- Configuration inspection: quantity, accessories specifications, list

- Outer box inspection: outer box appearance

Aging Testing

We conduct a standardized aging test to ensure the lasting performance of our KVM products. We conduct aging tests on all KVMs for more than 24 hours, during this period, the equipment will be continuously subjected to voltage shock tests using 100V, 120V, and 240V voltages.

- Each individual product will be shipped to you after strict testing by our factory.

Get Your KVM Switch Solution from A Reliable Supplier.

Our team of KVM specialists is available to assist you with your inquiries and KVM needs. We ensure vertical integration for all your OEM&ODM projects, from KVM product design to manufacturing and testing.